All our frames are tube to tube construction and hand built in-house using pre-preg carbon cloth cured in our tandem size composites oven.

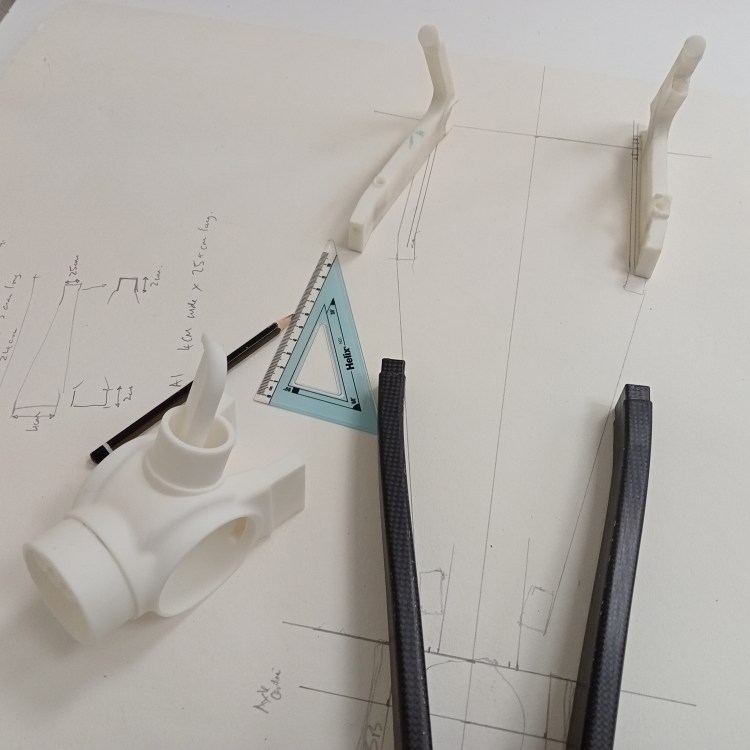

3D printing has become a core feature of design and modelling prototype parts through to high fidelity parts and on to carbon versions.

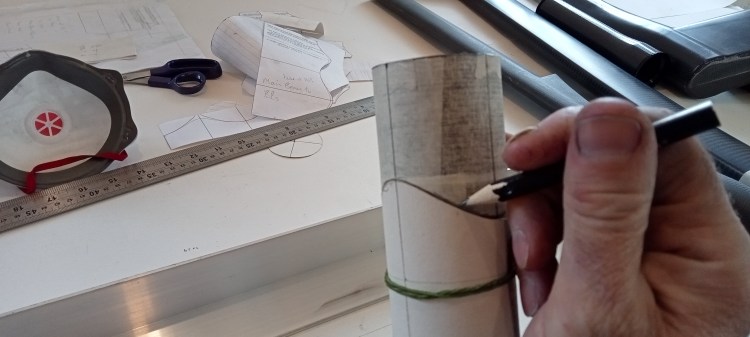

Handcraft skills are blended with the latest production techniques to create customised and always evolving designs that have efficient manufacturing processes to bring our customers a bespoke product.

Computer Aided Design has been added to the skill base so that further processes of moulding, waterjet cutting, CNC machining can be included into the manufacturing process to create high quality frame parts.

Low fidelity prototype dropout modelled in carbon fibre to check geometry and fit before further aesthetic styling of overall shape and style to a high fidelity prototype.

Comprehensive size ranges will be available ‘off the peg’ supported with detailed CAD models, with further custom geometry available on request.

Paint finish or a raw carbon finish is available on all tandems along with bespoke custom paint finishes through collaboration with specialist spray painters and artists.

Tandems for sale from August 2025 following full ISO safety testing of new frame designs. Please subscribe to the website for updates or reach out with an email to say hello! Jonny Charlton (Founder).